11000 Beograd, Pančevački put 104A

Technology

The production is equipped with modern machines known and trusted manufacturers: Kanthal Machinery, Granlund, CSM Machinery, Rossler and others. It is organized into three independent production lines, enabling her flksibilnost and provided a diverse selection of heating elements.

Due to its concept and equipment that differentiates us from other manufacturers, offers:

- Large production capacity

- Flexible production

- 100% control of the product during the process

- Testing, examination, product development

- New Product Development

Our products are cost-effective, reliable, durable, good structure, corrosion resistant.

Depending on the purpose of the heating element we care about the choice of surface pressure and power, that warm-up was optimal, but in order to avoid to load the heater.

Selection of pipes is done on the basis of the environment and the purpose for which the element is made, and depending on the working temperature shell element temperature of the working environment, as well as vrest media that is heated.

Tubular heaters are manufactured in lengths from 400 mm to 3000 mm, with that we can adapt the shape of customer request, taking into account the bending radius and its dependence on the type and diameter of the pipe heating element.

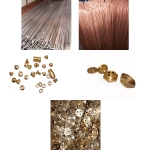

For the production of heating elements, we choose the best materials.

- All seamless copper tube Cu DHP which used in the production are subject to standard EN 12449 and EN 1057. Copper is an environmentally friendly material that can be recycled easily, and in accordance with that the acts and our production. Not only do we care about the quality, but also on resources.

- When choosing a stainless steel take care about its purpose and quality, and we choose AISI 309 or AISI 316L depending on the working environment heater. Welded stainless steel pipes are made of the highest quality tapes known manufacturers such as Otelinox, Outokumpu, Terninox, subject to standard EN ISO 9445

- Heating spiral made of a high-Kanthal D, Nikrothal-a, as well as the resistance wire of the famous German manufacturer BGH. FeCrAl alloys are used for temperatures up to 1300 ° C and are characterized by good resistance to oxidation. NiCr alloy has good ductility after use and excellent weldability.

- It is very important to select the correct sealant, to prevent moisture absorption in the magnesium oxide. Therefore, we select the best - Wacker